Blog - Author: Jim Krimmel

Author: Jim Krimmel

Zaclon is Born

Zaclon is Born! Inspired by the concept of operating DuPont’s Cleveland Plant as a standalone small business, the MTP (Management Training Process) team turned its attention to determining what that really meant and how far DuPont would go to implement the concept. The team determined that three key elements which could led to success were: Hiring their own sales force. Incentivizing all employees through a profit sharing and bonus plan. Shedding DuPont corporate overhead costs related to numerous corporate mandates and objectives. Armed with these needs, Joe Turgeon (Product Manager), Stu Schenk (Cleveland Plant Manager), and Jim Krimmel (Cleveland Operations Manager) traveled to Wilmington Delaware to convince DuPont management of these needs and to present the resulting economic projections for the Cleveland plant. The team met with limited success. Sales Force - The MTP team felt strongly that the sales effort being put forth by the DuPont marketing division was too diluted and lacking in focus. As Joe Turgeon put it, “What we have is a bunch of “one percenters” who might call on a Cleveland Plant customer on their way to a “real” account buying titanium dioxide or another of DuPont’s large volume products.” Cleveland Plant customers, mainly in the galvanizing and welding rod industries, while important, did not generate the kinds of sales revenue favored by DuPont. The

The Dupont Years

The DuPont Years (1928 – 1985) By: Jim Krimmel The DuPont Chemical Company was started in 1802 when a French immigrant, E. I. duPont journeyed to America to manufacture gun powder. DuPont’s first gun powder plant was located on the Brandywine River near Wilmington Delaware. Later in the 19th century, DuPont expanded into other explosives like dynamite and nitroglycerin but remained an explosives company until 1902. That year, three young duPont cousins – T.Coleman, Pierre S. and Alfred I. – purchased the company from their older relatives and began to transform it from an explosives manufacturer into a broad, science-based chemical company. Entry into the paints and coatings industry marked DuPont’s first effort to diversify beyond explosives. Nitrocellulose, in addition to being a raw material of smokeless powder, was also used as a lacquer to coat brass fixtures. In 1904, DuPont acquired International Smokeless Powder & Chemical Company, a leading manufacturer of nitrocellulose lacquer. Then in the late 1910s, DuPont took a fateful leap into textile fibers with the introduction of synthetic silk and cellophane, both derivatives of cellulose. Still, DuPont did

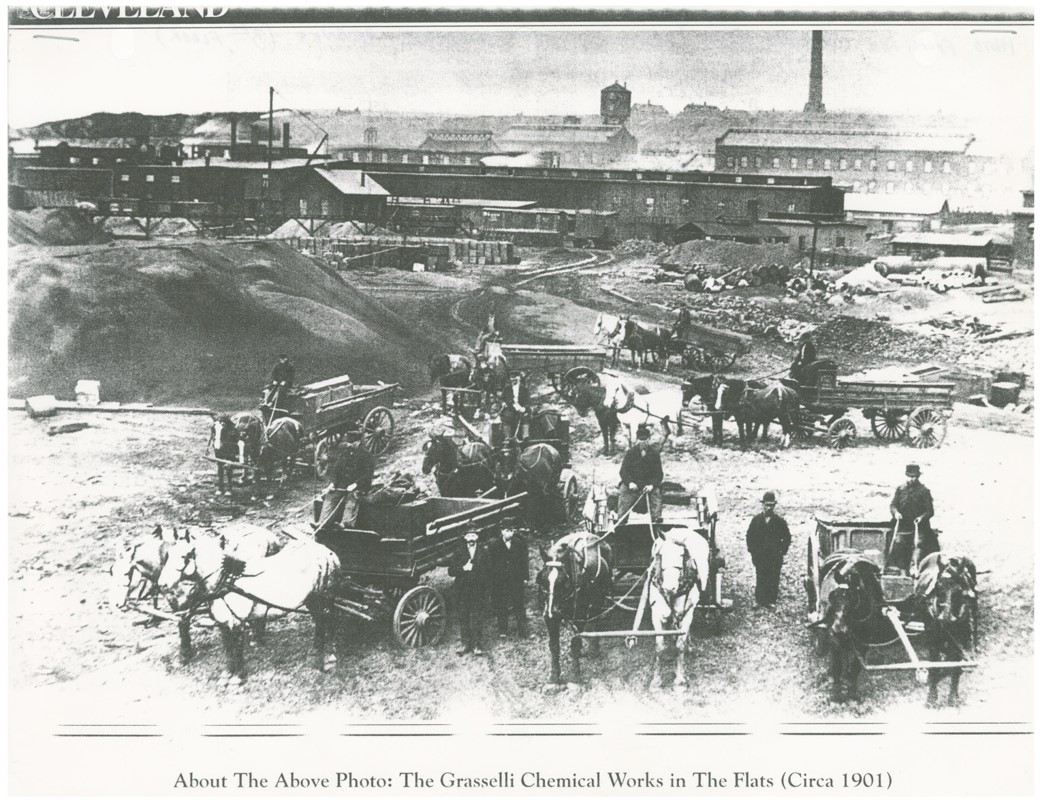

The Grasselli Years

With the startup of Grasselli’s Cleveland Plant in 1866, the plant began shipping sulfuric acid to John D. Rockefeller’s #1 refinery which was conveniently located ½ mile from Grasselli’s plant. But Rockefeller’s refinery was not the only one in Cleveland. In fact, by 1867 Cleveland had become the unquestioned center of the oil refining business in the United States with fifty oil refining plants. Large quantities of sulfuric acid were essential to wash the gasoline, coal oil, and the other products of distillation. The Grasselli Chemical company prospered. Because of the high demand for sulfuric acid in Cleveland, new sulfuric manufacturing plants soon sprung up including the construction of a plant by Marsh & Harwood directly across the street from Grasselli’s Cleveland plant. As a result of the overcapacity, prices and profits in the Cleveland market collapsed. Caesar and Eugene began to look elsewhere for lucrative markets and built manufacturing plants in New Jersey, Delaware, West Virginia, and Indiana. They also bought Lodi Acid Works near Pittsburgh in a 50/50 partnership with Marsh & Haywood. Although their business plan emphasized mainly sulfuric acid, Caesar and Eugene sought to soften the blows from the inevitable collapse of market sectors by adding new products to their production facility in Cleveland and elsewhere. In 1869, nitric acid and muriatic acid (HCl) were